Sulfuric Acid Battery Grade Dilute

Sulfuric acid dilute is being produced by our company through an automatic on-line dilution plant on IS standards. Major market players like EXIDE, SU-KAM, AMCO are now procuring dilute sulfuric acid directly.

Sulfuric acid dilute is being produced by our company through an automatic on-line dilution plant on IS standards. Major market players like EXIDE, SU-KAM, AMCO are now procuring dilute sulfuric acid directly.

Brief

A brief overview of the steps involved in the process of battery charging:

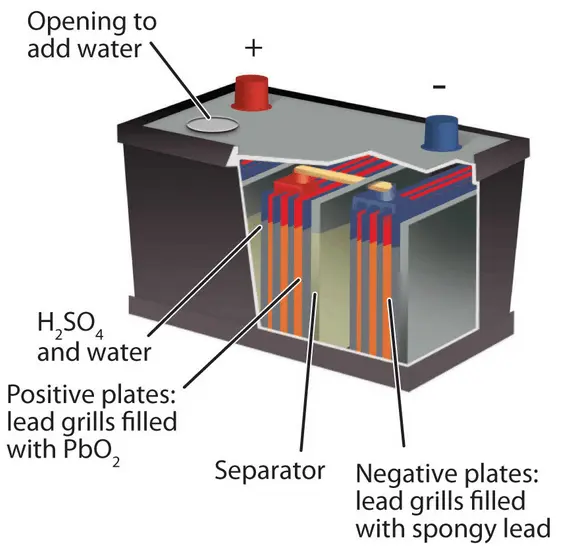

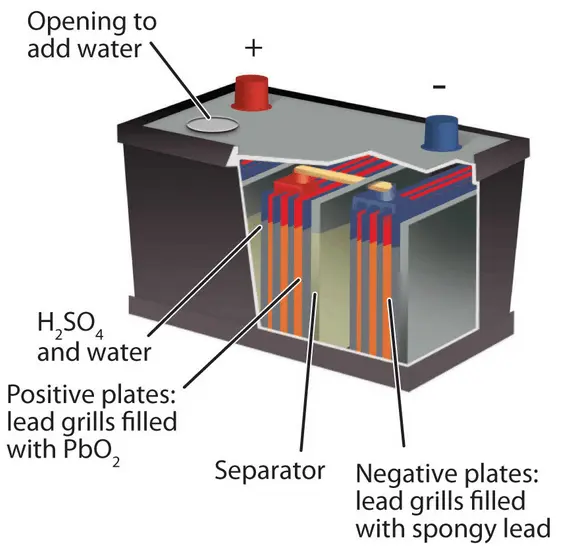

1. Procuring Sulfuric Acid B.G. Conc conforming to IS:266 of 1993 (amended to date).

2. Procuring of Distilled Water conforming to IS 1069.

3. Manually diluting Concentrated acid (Specific gravity 1.840) to dilute acid of Specific Gravity 1.220 & 1.400 using Distilled water. The process is HIGHLY EXOTHERMIC and DANGEROUS to the manual labour as well as the environment.

4. This hot dilute acid (Temp>100 ° C) is cooled down to 27 ° C to be able to be used for filling in dry batteries.

5. Cool acid is filled and batteries are put up for charging on a charging unit.

As you may observe that steps 3 & 4 describes the vigorous nature of the process of dilution.

Sulfuric acid dilute is being produced by our company through an automatic on-line dilution plant on IS standards. Major market players like EXIDE, SU-KAM, AMCO are now procuring dilute sulfuric acid directly.

ADVANTAGES of Procuring Sulfuric Acid Dilute:

QUALITY WISE:

1. Most charging depots are in remote location which have scarce availability of IS standard Distilled water.

2. Diluting in vessels (due to high temp involved) might lead to increase in impurities like Fe & Cu. Increase in Fe & Cu concentrations even in PPM level can reduce battery life. Utmost care has to be provided to the dilution process which an automatic dilution process offers.

3. Irregular specific gravity of the acid may be fatal to battery.

4. Impurities in dilute sulfuric acid hampers battery life.

ECONOMICALLY:

1. Cost of procuring dilute sulfuric acid shall always be less than that of making the same from concentrated acid at the depot.

2. Vessels and other machinery used in dilution shall not be required.

3. Cost of skilled an unskilled manpower saved.

4. Cost of procurement of distilled water saved.

5. Less space required for the whole process.

These are few benefits along with the improvement in the quality of the battery charging.